DTY Tube Making Machines

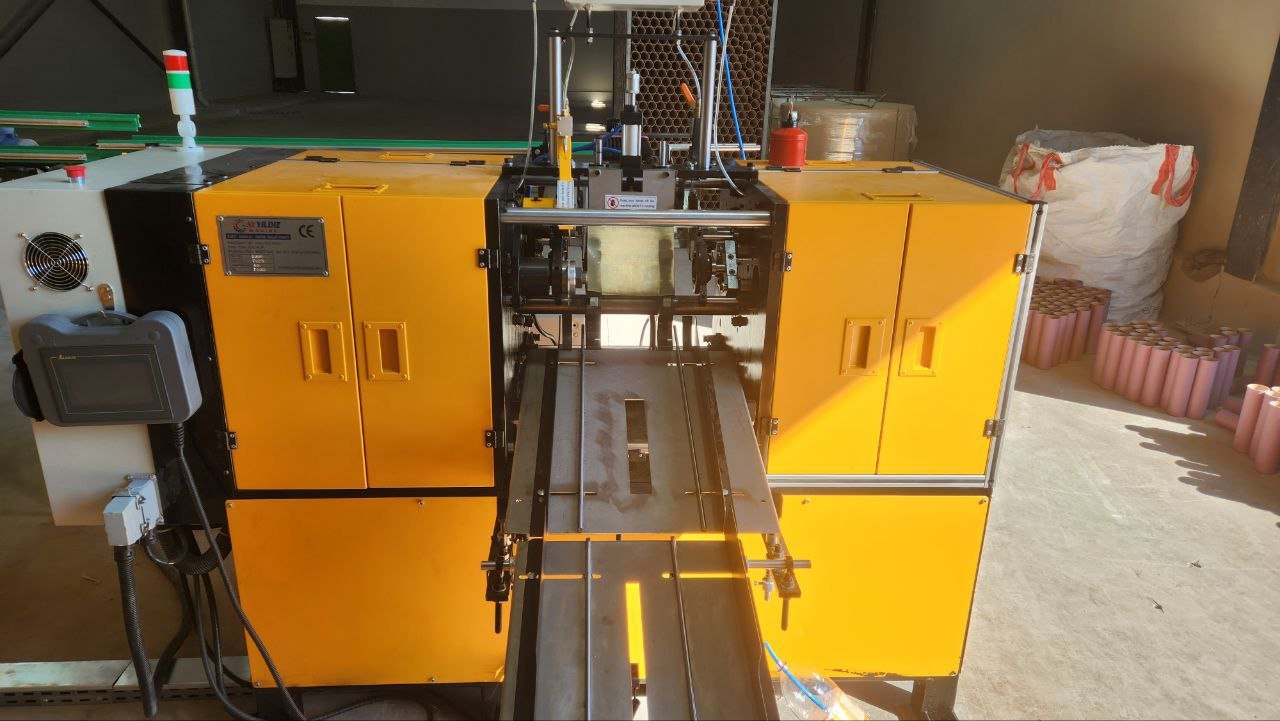

| Capacity of Paper Hanging Unit | 5 Layers to 10 Layers |

|---|---|

| Paper Tube&Core Thickness | 1mm - 5mm Arası |

| Paper Tube&Core Diameter | 54 mm / 69 mm Arası |

| Paper Tube&Core Length | Min:170 mm - Max: 290 mm |

| Cutting System | Multi Blade Servo System |

| Machine Speed | 25 met / min |

| Electrical Quality | Siemens PLC,TouchPanel |

| Capacity of Machine | 50.000 Pieces of Day |

| Drying Oven Unit | |

| Tube Mouth Curling | |

| Auto Packaging |

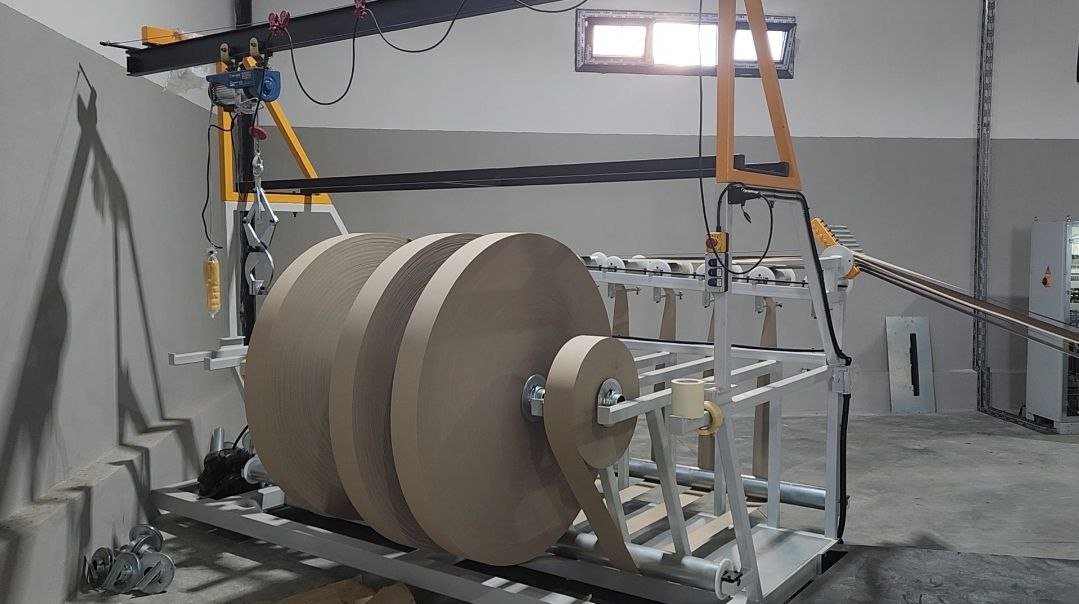

DTY Tube Machines are special machines that produce bobbins used for DTY yarn production. These machines are generally designed to produce cores made of paper or cardboard.

What does DTY Tube Machines do?

The machines that produce the cores (paper tubes) attached to the DTY yarn producing

machine play an important role in the DTY yarn production process. Its functions are:

Bobbin Supply: These machines provide the production of bobbins used for DTY yarn

production. Bobbins are a type of bobbin used for winding and storing threads. Bobbin

winding machines produce bobbins made of paper or cardboard and wind the threads onto

these bobbins.

Bobbin Sizing: The machines have cutting mechanisms that allow the bobbins to be cut in

certain diameters and lengths. This enables the production of tubes to standard sizes. The

sizing process facilitates the subsequent insertion and handling of the bobbins into the

spinning machine properly.

Bobbin Winding: Bobbin winding machines have winding mechanisms that ensure that the

bobbins are wound securely and that the threads are wound properly on the bobbin. In this

way, it is ensured that the threads are wound on the bobbins regularly and neatly and that

the threads are held securely.

Bobbin winders are an important tool to increase productivity in the DTY yarn production

process. These machines enable the production of bobbins at high speed and with precision,

thus making the yarn production process more efficient. In addition, the quality and

dimensions of the produced bobbins are also an important aspect of these machines, because the correct size and properly wound bobbins are made suitable for later use of the

threads.

What are the Usage Areas of DTY Paper Tube Machines?

The machines that produce the bobbins (paper pipes) attached to the DTY yarn producing

machine have a wide usage area. Here are some important uses:

Textile Industry: DTY yarns are generally used in weaving, knitting and carpet production.

Bobbins are necessary for collecting and storing these yarns. Bobbin winding machines are

important machines used in the textile industry for the production and processing of DTY

yarns.

Yarn Production Facilities: Yarn production facilities are facilities where different types of

yarn are produced and processed. DTY yarn production requires bobbins and bobbin

winding machines are used as part of yarn production in these plants.

Synthetic Yarn Production: DTY yarns are generally produced from synthetic materials,

especially polyester and nylon. In plants where such synthetic yarns are produced, bobbin

winding machines are used to produce bobbins.

Yarn Storage and Distribution Centers: After yarn production, yarns wound on bobbins are

kept in storage and distribution centers and sent to the relevant customers. In these centers,

bobbin winding machines are used to produce bobbins and wind the threads correctly.

Bobbin winding machines play an important role in the production and processing of DTY

yarns. These machines ensure that the bobbins are produced in the correct size and quality,

and ensure that the yarns are wound properly, increasing the quality of the end product.

What are the Features of Ayyıldız Makine DTY Bobbin Machines?

Our DTY tube producing machines, which belong to our company, are the latest technology

and serve all the demands of the sector. Servo system has full electronic length cutting

technology, electrical equipment is Siemens.

There is an oven in this machine to remove the moisture from the bobbins. The bobbin that

enters the oven stays in the oven for about 5 minutes and the humidity on the bobbin is

reduced. The strength and hardness value of the core that has been baked and whose

moisture has been reduced increases.

Our machine has a rolling unit after the oven unit. Our quilling unit performs the inward

bending of the ends of the bobbins. With this process, it is aimed to catch the yarn from the

bobbin more easily and in a shorter time.

The inner diameter and outer diameter of the product to be crimped vary significantly

according to customer needs. We produce solutions according to each customer's needs.

After the mouth twisting unit comes our automatic stacking unit. In this unit, the bobbins are

packed.

Again, in line with our customer's request, stacking and packaging operations are carried out

in a cardboard box or a linoleum bag. In addition , product accessories such as lines ,

notches , etc. can be integrated on the bobbins and products can be produced in line with

customer demand . Textile bobbins used in the industry mainly have inner diameter

dimensions such as 54mm - 56mm - 69mm - 73 mm. Ayyıldız Makine, which has the

technical possibilities and capabilities to produce both industry standards and all non-

standard products, is based on customer satisfaction and can produce machines that can

produce all cores in line with customer demands.